Contact us!

Switchboard number:086-0518-85380151

15312113188 Manager Zhu

|

|

|

|

|

|

|

Assembled Inner Floating Deck |

The assembled inner floating deck shall be used together with the tank where the storage medium like volatile liquid petroleum products are stored, because it can reduce the natural volatilization of media and is helpful for energy conservation, loss reduction, safety, environmental protection, as well as the increase of economic benefit.

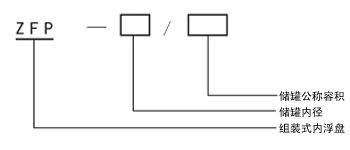

Instructions for model Instructions for model

Example Example

The aluminum floating deck installed in the inner floating roof tank with the inner diameter of 17m and nominal capacity of 3000m3 is ZFP 17/3000.

List of main models List of main models

No. |

Inner diameter of tank (m) |

Nominal capacity of tank m3 |

Model of floating deck |

Weight (kg) |

Buoyancy (kg) |

1 |

5.5 |

200 |

ZFP 5.5/200 |

392 |

823 |

2 |

7.5 |

300 |

ZFP 7.5/300 |

563 |

1210 |

3 |

8.2 |

500 |

ZFP 8.2/500 |

606 |

1291 |

4 |

9 |

600 |

ZFP 9/600 |

672 |

1447 |

5 |

10 |

800 |

ZFP 10/800 |

746 |

1604 |

6 |

11.5 |

1000 |

ZFP 11.5/1000 |

953 |

2011 |

7 |

14.5 |

2000 |

ZFP 14.5/2000 |

1322 |

2776 |

8 |

17 |

3000 |

ZFP 17/3000 |

1661 |

3588 |

9 |

21 |

5000 |

ZFP 21/5000 |

2184 |

4696 |

10 |

30 |

10000 |

ZFP 30/10000 |

4339 |

9285 |

11 |

42 |

20000 |

ZFP 42/20000 |

8835 |

18288 |

12 |

44 |

30000 |

ZFP 44/30000 |

9821 |

20428 |

The abovementioned parameters of tank are made by reference to the Steel Vertical Cylindrical Inner Floating Roof Tank Series HG21502.2-92.

Note: Our company can design and manufacture floating decks of special specifications as required by users.

Specifications / standards for design, manufacturing and acceptance Specifications / standards for design, manufacturing and acceptance

- 1. All openings on the floating deck and accessory position are determined according to tank construction drawing provided by Party A.

- 2. The manufacture and installation of the floating deck shall follow Enterprise Product Standard-Internal Floating Roof of the Tank and Installation and Operation Specification of Floating Deck.

- 3. It follows ISO9001-2012Quality Management System. The main executive standards include:

- GB/T3190-96 Chemical Composition of Aluminum and Aluminum Alloy Processing Products

- GB/T6892-96 Wrought Aluminium and Aluminium Alloys--Extruded Profiles for Commercial Usage

- GB/T3880 Aluminium and Aluminium Alloy Rolled Sheet

- GB13348 Safety Rules of Static Electricity with Relation to Liquid Petroleum Products

- SH3046-92 Code for Design of Vertical Cylindrical Welded Steel Oil Tanks in Petrochemical Industry

- API650 Appendix H of Welded Steel Oil Tanks

- HG/T2809-96 Rubber Sealing Ribbons of Soft Sealing Device of Floating Roof Tank

- Q/320700JAQ,01-2014 Internal floating roof Used for the Tank

Composition of structure Composition of structure

|

|

Product features Product features

- ?It has a special equilateral triangle unit structure and a high-strength frame.

The fame of floating deck is constituted by some equilateral triangle units and the girder of the structure extends to the edge of the frame which has high strength and good stability; the structure can produce resistance to quickly reduce and absorb the impact on the storage medium during the operation of floating deck.

- ?Small-sized buoys are uniformly distributed so as to increase the operational reliability.

The buoys are separated from the frame, with a large number, and they are distributed uniformly so as to avoid the floating deck tilt and jamming due to leakage of individual buoy and increase the operational reliability of floating deck.

- ?The outer buoys are distributed in the form of ring so as to ensure the sealing reliability and stability during operation.

The floating deck adopts a special form in the arrangement of buoys that floats are uniformly distributed around the peripheral sealing belt in the form of ring so as to make forces uniformly distributed on the sealing belt, overcoming the friction between the sealing belt and the tank wall during the operation of floating deck and ensuring the safety operation of floating deck, without jamming.

- ?The product has remarkable effects in terms of energy conservation and loss reduction, with the loss reduction ratio above 98%.

The design of floating deck ensures there is a small space for oil and gas, effectively reducing the evaporation amount of the storage medium, with the loss reduction ratio above 98%. For specific performance, see the Economic Benefit Analysis.

- A high utilization ratio of tank

Since the oil and gas space inside the tank is generally lower than 120mm and the whole structure is only 320mm thick, in comparison with floating decks of other structures, the floating deck increases the oil storage space and improves the utilization ratio of tank.

- ?It can be easily and quickly installed and repaired.

The floating deck is connected by bolts, not needing welding, especially suitable for transforming tanks; the parts and components are manufactured by adopting the mold method so they have good interchangeability and universality, and all parts and components can be separately replaced by entering in the tank via the tank manhole, which is easy for installation and maintenance.

- ?With corrosion resistance and long service life.

The main body of floating deck is made of high-quality material, with good antiseptic property and long service life, and aluminum, carbon steel and stainless steel are optional; the sealing material varies with the storage medium, and it shall have such excellent properties as electric conduction and wear resistance, good elasticityNot easy to crack����。

- ?Good safety

The static electricity is perfectly and standardly conducted, without potential electrostatic hazards, and there is no need for welding installation to ensure the safety use of floating deck.

Material of parts and the main body Material of parts and the main body

- ?The cover plate adopts the 3A21 rust-proof aluminum rolled plate with the thickness of 0.5mm;

- ?The frame adopts 6063 aluminum high-strength rust-proof aluminum profile, and the coating thickness is 0.0172-0.0116mm;

- ?The buoy adopts seamless aluminum tubes, and the wall thickness of buoy is 1.7mm;

- ?The accessory adopts 3A21 material;

- ?Tongue-shaped or bladder-type tape; the rubber type shall depend on the medium.

Parameters of main components Parameters of main components

Economic Benefit Analysis Economic Benefit Analysis

Exampled by the 1000m3 dome-roof tank and the floating-roof tank equipped with ZFP 11/1000 aluminum inner floating deck:

Type of tank |

Medium |

Capacity |

Big breathing loss /year |

Small breathing loss /year |

Total annual loss (ton) |

Loss per time |

Annual turnover frequency |

Total |

Loss per time |

Annual turnover frequency |

Total |

Dome-roof tank |

Gasoline |

1000m3 |

158kg |

20 |

31.68T |

72.9kg |

300 |

21.87T |

53.55 |

Floating-roof tank |

Gasoline |

1000m3 |

16.7 |

20 |

0.334T |

1.34kg |

300 |

0.402T |

1.07 |

| Note: The aforesaid data are calculated based on the storage capacity of 680 tons and mean temperature of 28℃. |

Annual loss reduction 52.48 |

According to the contrast data above, compared with the dome-roof tank of the same volume, the 1000m3 floating-roof tank equipped with inner floating deck can save oil up to 52.48 tons every year and make the energy conservation and loss reduction ratio above 98%.

Technical performance and index Technical performance and index

- The total buoyancy of the floating deck is more than two times of total weight of the floating deck (buoyancy-weight ratio>2);

- The appearance quality is smooth and clean without mechanical damage. The component assembly connection is reliable and fastening without looseness;

- The structure design of the floating deck is novel. On condition that the same material is used, the floating deck has high strength and good stability;

- When the floating deck drops bottom or floats, all setting positions of the beam and the buoy shall bear concentrated load no less than 2200N (three persons walk on it);

- Adopt small size float and keep uniform distribution so as to avoid the floating deck tilt and jamming due to damage of individual float;

- The aluminum tube is used for all floats. The floats all pass 0.2MPa hydrostatic test. Make sure leakage does not happen to the weld;

- The aluminum alloy profile with thickness more than or equal to 2mm is used for the frame. The depth of outer ring edge immersed in liquid storage is ≥ 100mm;

- The breather valve is designed according to API Standard H.6.2. The minimum opening pressure is 1000pa;

- Set up outriggers at the bottom of the floating deck. The height of the floating deck is 1800mm. The accessory equipment at the bottom of the tank does not interfere with the component on the floating deck. Carrying capacity of outriggers shall be more than critical stiffness value of the floating deck;

- The manhole of the floating deck is open and closed freely. The flip surrounding is enclosed. The depth of lower frame immersed in fluid storage is ≥ 100mm. Besides, provide a ladder to operation personnel for climbing up and down from the floating deck;

- The bladder-type structure is used for surrounding sealing tape. Select corresponding rubber material according to liquid storage in the tank. Make sure using period in normal condition is more than 15 years;

- The panel thickness is 0.5mm. Implement sealing of lapping zone of adjacent cover plates with sealing strip. The distance between riveting points is ≤150mm;

- Anti-rotary device of the floating deck can prevent the floating deck from rotating effectively when it floats up and down;

- The outside of sealing belt around the floating deck shall contact the tank wall closely without leakage when the floating deck drops bottom or floats to the highest position;

- Make sure to set static electricity guiding device between the floating deck and the tank. Use 3mm stainless steel wire rope. The device meets the requirements of GB13348 Standard. The tank resistance is <10Ω.

|

|

| |

|